What’s New at Integrity

Integrity’s HD2 is located at 3165 Devon Drive – right across the street from Integrity HD. At approximately 33, 500 square feet, HD2 boasts a large and open shop floor, programming office, café-inspired lunch room, and boardroom.

The Facility

Integrity HD is one of the first multi-bay manufacturing facilities in our area constructed with a single column design, making the interior of the plant both aesthetically captivating and easier to maintain from a 6S perspective. Each bay houses a 50-ton crane and a 16×16 bay door for deliveries. Prior to leaving the shop, each job will pass through the inspection area to ensure it meets all Integrity standards including surface finish, precision of all functional features and completeness of job.

South-facing windows on the shop floor and in the break room eliminate the need for skylights and allow an abundance of natural light into the facility, making HD2 a happy home for many hardy plant varieties. Floor-to-ceiling glass walls on the second storey meeting spaces overlook the shop floor and further add to the openness within the facility.

On the green side of things, HD2’s parking lot is prepared for 4 EV charging stations when installation is complete. Additionally, HD2 is home to Integrity’s first VFD-style compressor designed for energy efficiency.

The Machines

HD2 houses 8 state-of-the-art CNC machines:

- 2 Correa Fox

- 4 DMG 270u with pallet changers

- 2 DMG 270p

The machines feed into a centralized conveyor system to automatically transport steel chips outside into the appropriate disposal bin.

HD2 cuts an average of 11 jobs per week. Depending on the job, with the palletized system on the DMGs and the use of sister tooling, lights out run time helps the team at HD2 achieve 24/7 machining.

The Department

HD2 is home to Integrity’s Stage 1 MES department. Stage 1 receives blocks from across the street at HD that have been saw cut, roughed, eye bolted, semi-ed to 60 thou, and treated in the oven. After landing in Stage 1 at HD2, blocks go through complete 2D and heavy cutting. This is where the qualifying of the blocks starts so that all other machining departments can accurately do their work.

The Stage 1 team is responsible for establishing FCS, skimming and squaring the block, completing all side and back work (less any required gundrilling), then flipping the job to get the finish machining process started. By semi-cutting the molding surface, Stage 1 helps to ease cutting time and machine load for the next department.

The Team

Stage 1 MES is made up of 10 Programmer/Machinists and led by Mike Litster, Team Leader and Plant Manager. 80% of Stage 1 team has been with Integrity for over 5 years, with 3 team members’ tenure exceeding 10 years. We recently sat down with the Stage 1 team to discuss their department and working at HD2:

On what makes the team great…

- Stage 1 is like a family – they would do anything to help one another and often all jump in to assist in tasks

- No one is afraid or unwilling to do any job

- Working with such a close knit group makes even routine work tasks fun and fills their day with laughter

- Everyone programs and operates machines – they don’t have one person to one machine – this allows everyone to be part of each job and fosters a team atmosphere of shared responsibility and shared growth

- Having Mike as a leader makes them a better group. He puts a lot of responsibility on the team but trusts them to do their jobs correctly

On working at HD2…

- It’s very exciting to see the company’s growth and to be part of the change firsthand

- The facility is quiet and clean

- It’s a privilege to work hands-on with new machines and industry-leading technology

- The building being designed for the specific Stage 1 processes is incredibly efficient

- Even small tasks have been automated, so now certain things that used to add 15-20 minutes to a job have been streamlined, allowing that time to be utilized in a more productive way

- Capabilities allow work to be delivered at the highest quality

A strategic partnership.

Integrity is thrilled to announce our strategic partnership with Elmann, a renowned manufacturing company based in Italy.

This collaboration brings together our shared commitment to excellence, cutting-edge technology, and unrivaled expertise, propelling the Integrity Team to new heights of innovation and success.

Some key highlights:

- Advanced Research and Innovation, Co-Design & Simulaton

- Reliability of production process, live mold manufacturing

- Status documented and shared with customers

- Internal production of Micro-Optics

- FemtoLaser for micro structures, texture and graining

- PUR and FOIL process for IMD, IME, IML applications

- Reactivity in managing modifications

- Service → specialized teams for on-site support

Synergy of Expertise

Together, we bring a wealth of expertise to the table, ensuring that our customers receive nothing short of the most advanced, tailored, and globally reliable solutions available.

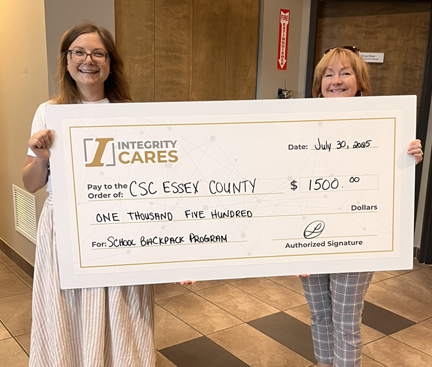

Over the past several weeks, the Integrity Cares Board has been busy hosting several local organizations for donation cheque presentations, where we also had the opportunity to learn more about how our support will help their causes.

Community Support Centre of Essex County’s School Backpack Program – $1500

The CSC’s School Backpack Program provides access to new, fully stocked backpacks for students in need in our community. Our $1500 Integrity Cares donation allowed the CSC to purchase 120 fully stocked backpacks for the 2025-26 school year. In total, they anticipate a need of 300 backpacks for this year and that need is growing year-to-year: in 2023 they gave out 40 backpacks and in 2024 they distributed 80.

Lola’s Roundtable – $1500

Lola’s Roundtable provides programming for adults with disabilities as a means to give families respite and options for daytime care once young adults have aged out of the school system. Programming focuses on building life skills, fostering independence, and establishing meaningful relationships. Our donation will help fund core programming, including community activities, cooking/life skills development, and transportation services.

Feeding Windsor Essex’s Pet Food Bank – $1500

Feeding Windsor Essex has been serving Windsor-Essex County for 10 years. Last year alone they served over 220,000 meals to our community. In addition to helping feed people in need in our area, they also offer a Pet Food Bank. When people struggle with food insecurity, they may often forgo a meal for themselves to make sure that their pet is fed. The Pet Food Bank is there to provide pets with food so that people can take care of themselves. Our donation will help sustain their ability to feed 400-500 animals per month.

Scouts Canada: Camp Cedarwin – $1500

Camp Cedarwin is our area’s local Scouts Canada campsite, located on 74 acres of land on the Arner Townline. Camp Cedarwin has been in operation for 56 years and is run strictly by volunteers. They average 1100-1200 youth through the camp per year, in addition to 500-600 adults. Camp Cedarwin has recently built a new welcome shelter that provides a protected place for camping gear when youth are dropped off. Our donation will help fund the completion of this project through construction of a deck floor that will keep campers’ gear protected from rain and snow.

Natural Pathways – $1500

Natural Pathways is an outdoor forest school located in Harrow aimed at connecting young people with nature. They offer programming to children and youth intended to spark curiosity, foster resiliency, and develop core memories centered in nature. All programs are based on their core values of respect, connection, collaboration, inclusion, kindness, and awareness. Our donation will specifically target their Wellness in Nature program, developed in partnership with the Ted Farron Family Foundation, for young girls aged 9 to 13. Wellness in Nature supports youth mental health by harnessing the power of nature to heal, inspire and transform, offering young girls a safe place to get off their electronic devices and out of their comfort zones.

2026

Year of Operational Excellence.

We are raising the bar once again.

Integrity has always been driven by operational excellence, in fact, it has been fundamental to our growth and success as a world class company.

Knowing this and its importance, we are making operational excellence one of our primary focuses this year in all areas of the company.